Using a Ball Mill for Black Powder Production: How It Works

Making black powder provides the foundation for dazzling fireworks displays and explosive effects. The use of a ball mill is essential in the production of this pyrotechnic mixture. It is a tool for changing raw materials into finely milled products.

It is a powerful combination that is essential to several pyrotechnic undertakings. We will discuss the internal workings of a ball mill for black powder.

Continue reading to find out more about using a ball mill to make black powder and how it works.

Contents

Loading the Mill

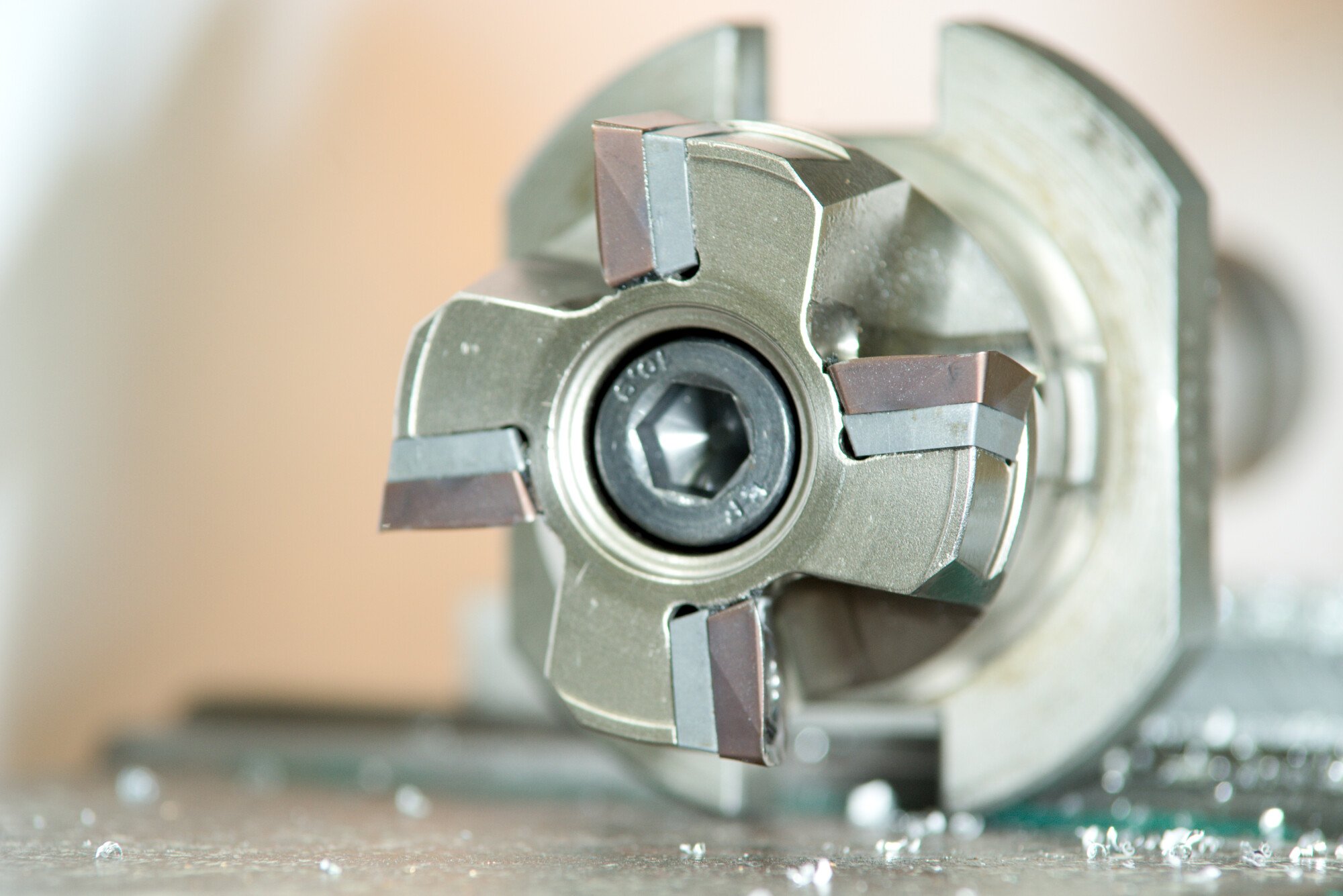

A cylindrical shell revolves around its axis to form the ball mill. Metal balls (or other grinding medium) are fed into the mill together with the components of black powder (potassium nitrate, charcoal, and sulfur) within the shell. Using a ball mill to make mixed black powder is a specific operation, but safety is crucial.

Place the media and any other materials in a container. When the container is filled, it is linked to the rolling platform, and the milling process begins.

Grinding Process

As the ball mill turns, the balls within it cascade and tumble, grinding the components into a fine powder. The grinding operation decreases particle size and ensures proper mixing of the parts. It grinds materials together in a spinning cylinder using balls as the grinding medium.

The balls fall back into the cylinder and onto the material to be pulverized as the cylinder rotates, producing a fine powder. The size of the balls is determined by the intended result of the grinding ingredients. The ball mill must be run at optimal speed and with suitable motor power.

You may seek out or go to the website of Shop Grinding Mills, which has an extraordinarily high ratio of technically experienced and qualified staff-a legacy from the founder, a gifted craftsman with an innate sense for equipment.

Duration and Speed

The time of the grinding process and the mill’s rotating speed are crucial parts. It influences the final particle size and the quality of the black powder. Longer grinding durations and faster-rotating speeds produce finer powder.

Over-grinding the combination might result in undesirable effects or risks.

Safety Considerations

It is critical to take necessary safety precautions when using a ball mill to make black powder. It involves wearing suitable safety equipment. It provides adequate ventilation to disperse any hazardous gases or vapors. It also keeps the workspace free of combustible materials.

Final Product

The resultant black powder is carefully removed from the ball mill when the grinding operation is completed. Because the powder is sensitive to friction, impact, and heat, it must be handled with caution.

Storage

The black powder generated should be stored in a cold, dry area away from sources of fire, under local rules and safety recommendations. It makes it ideal for black powder manufacturing since it can be transported to another location for storage or usage.

Benefits of Utilizing a Ball Mill for Black Powder Production

Using a ball mill for black powder manufacturing offers several advantages. It also includes greater efficiency, safety, and powder quality. It is simple to use, with low setup and operational expenses.

Ball milling is an excellent option for individuals who want to make their own black powder. Try using a ball mill for fluffy powder manufacturing to get all the advantages!

Did you find this article helpful? If so, check out the rest of our blog for more informative content.